Precision Stamping Technology

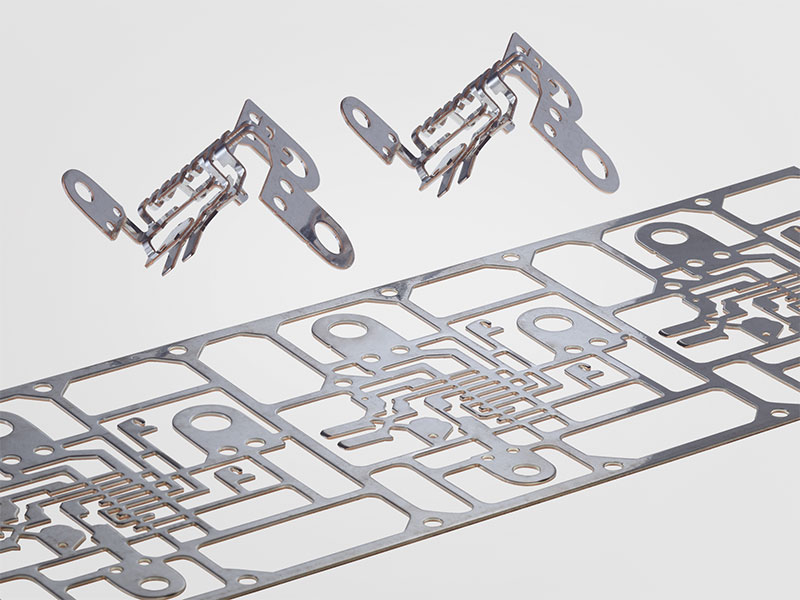

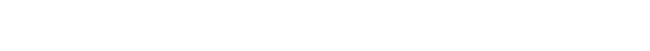

Stamped parts, especially micro-stamped parts, demand the highest level of perfection, especially when it comes to the serial production of complex precision parts. These include, for example, stamped parts with a bondable surface or multi-part stamped parts where several parts are "married" in a one-step process.

One prerequisite for this is our state-of-the-art machinery, which enables us to perform the most precise milling, precision grinding as well as wire eroding within the range of µm. We deploy the exclusive Japanese Yasda machine* to ensure results of the highest precision with High-Speed Cutting (HSC).

*(hapema is one of only three manufacturers in Germany certified to use Yasda technology).

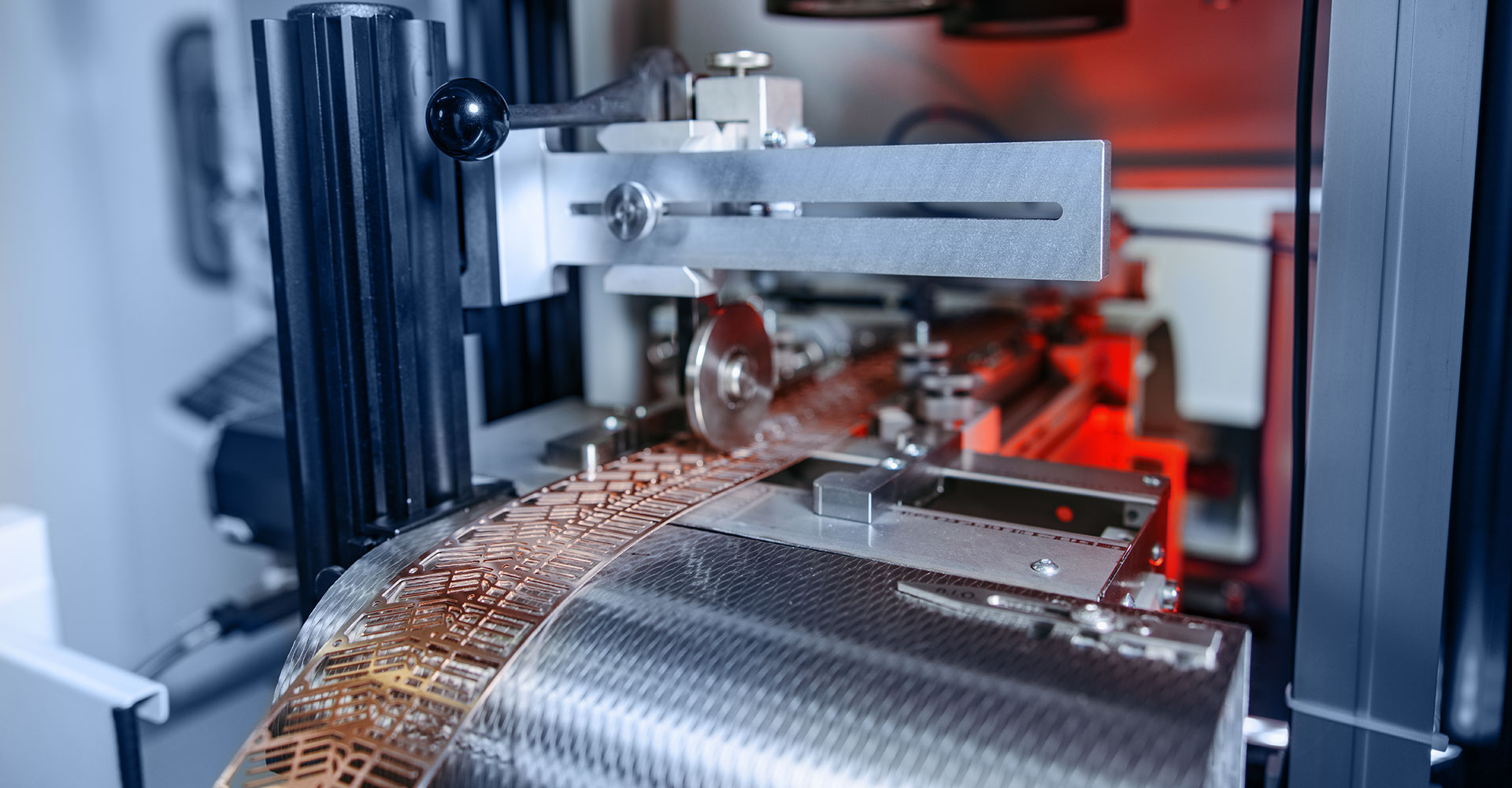

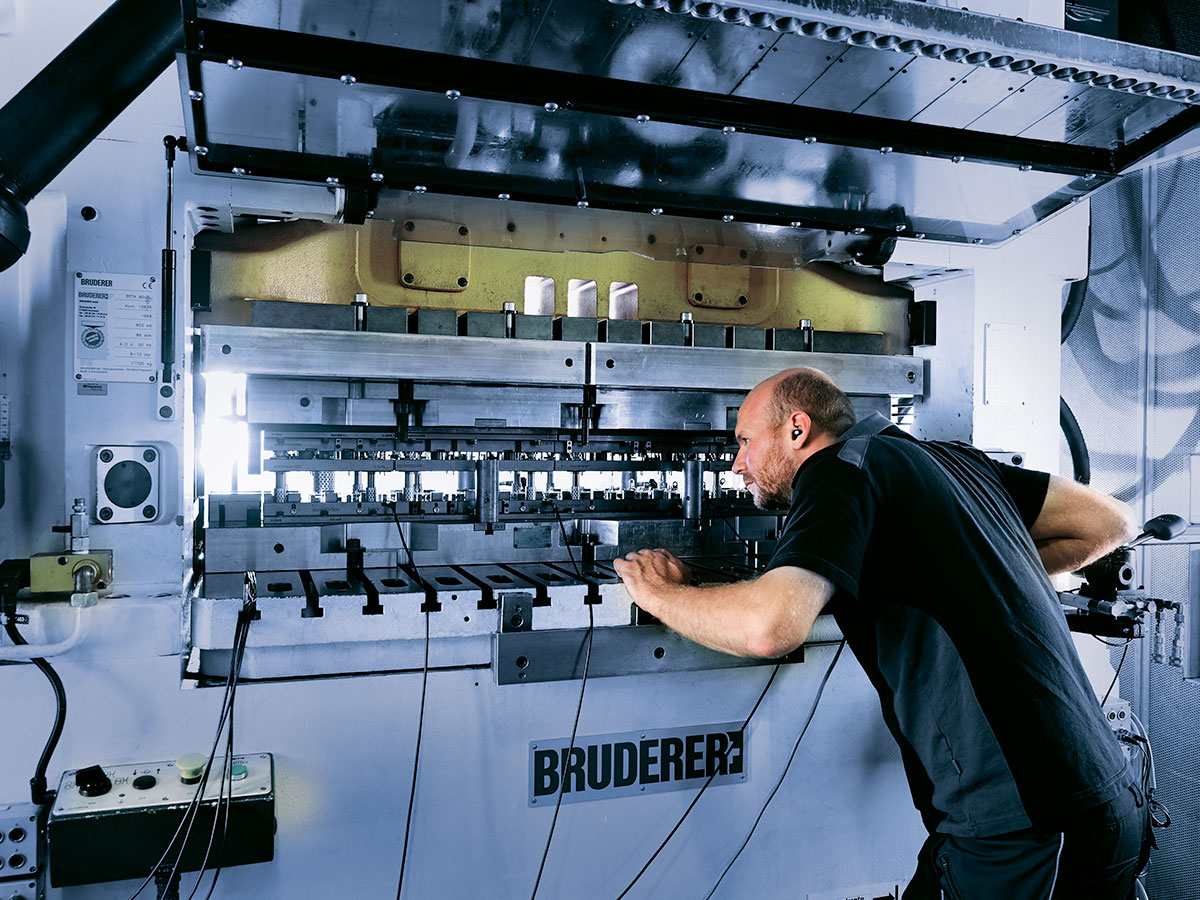

Equipped with 8 Bruderer stamping presses, we produce stamped parts in multi-shift operation using strip thicknesses from 0.05 to 1.50 mm and a strip width of up to 200 mm with every standard material and surface:

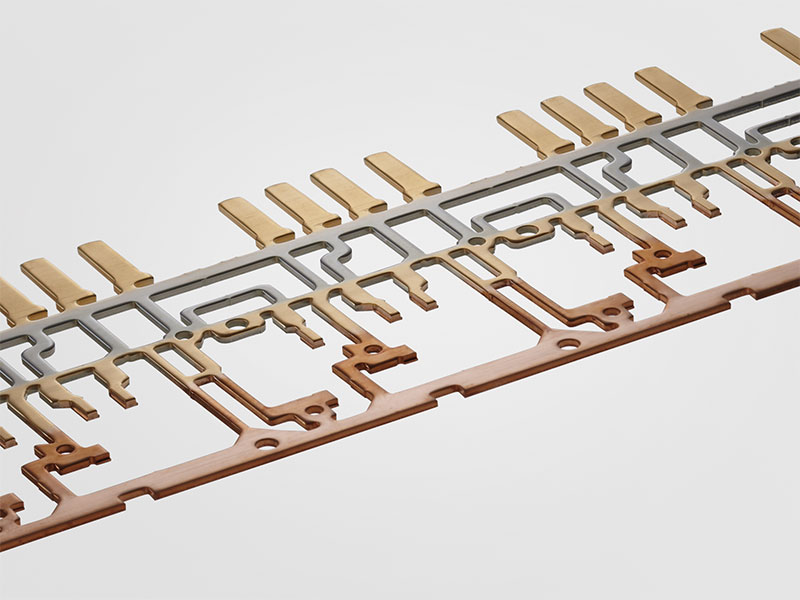

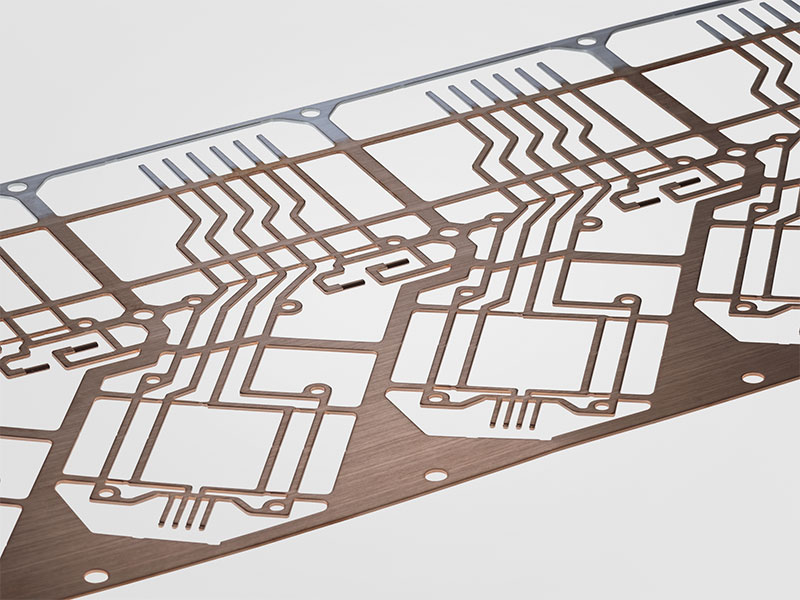

- Punched grid

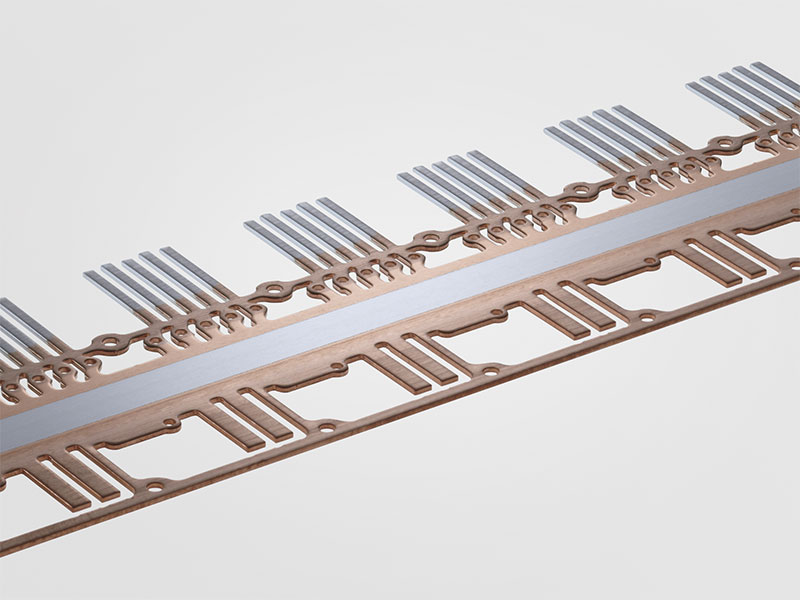

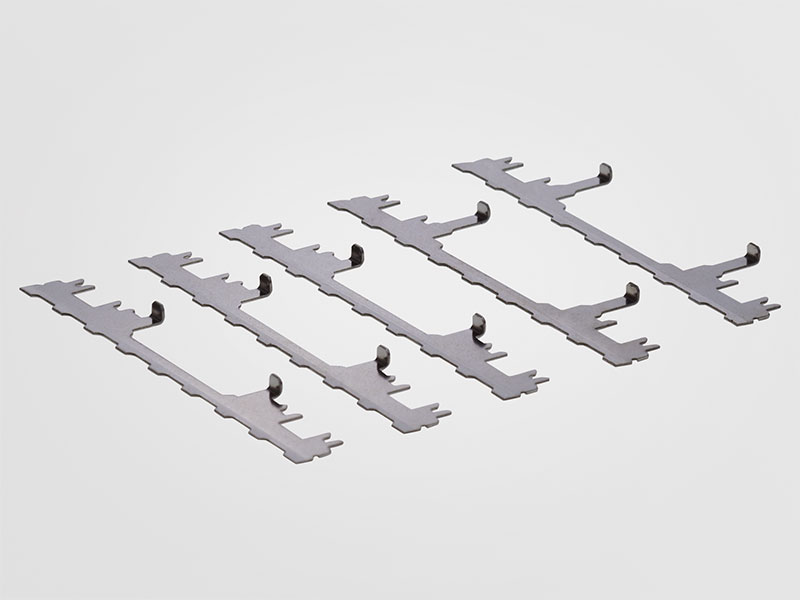

- Patented press-fit zones (e.g. EloPin®)

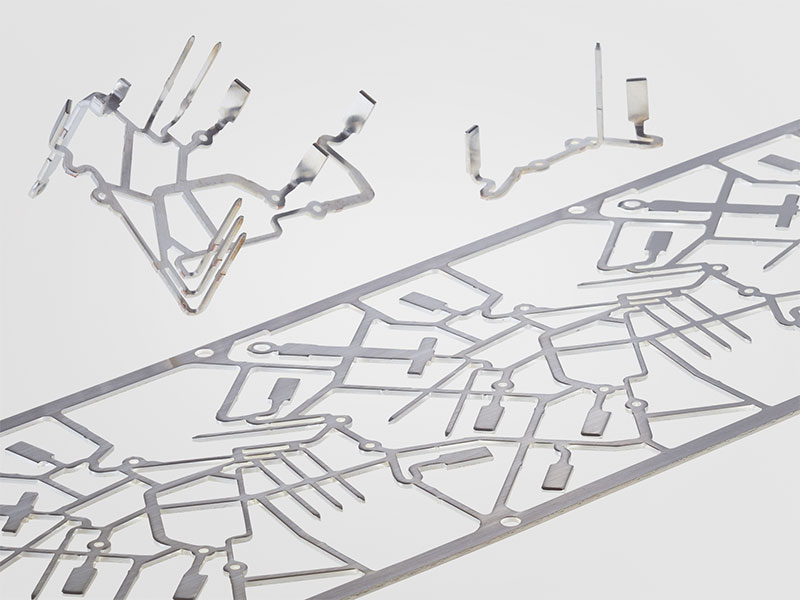

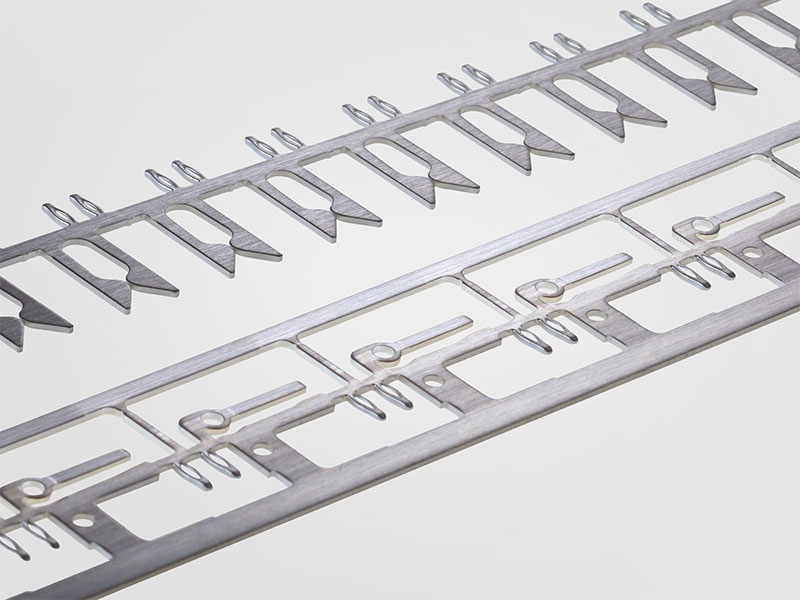

- Micro-stamped parts

- Punched grids with bondable surfaces (e.g. AlSi, NiNiP, Bond-Ni, Bond-Au, NiPdAu)

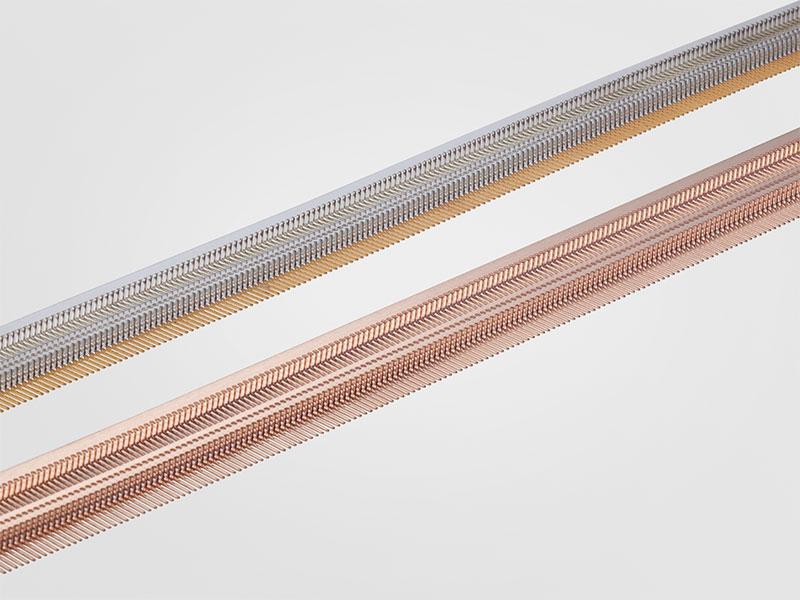

- Punched grids with wire- or contact rivets

- Socket contacts (stamped and rolled)

- Multi-part stamped parts, e.g. main body of socket contact (several parts are "married" in a one-step process)

- Drawn parts

- Sample parts (stamped, laser-machined or eroded – bent with auxiliary tools)

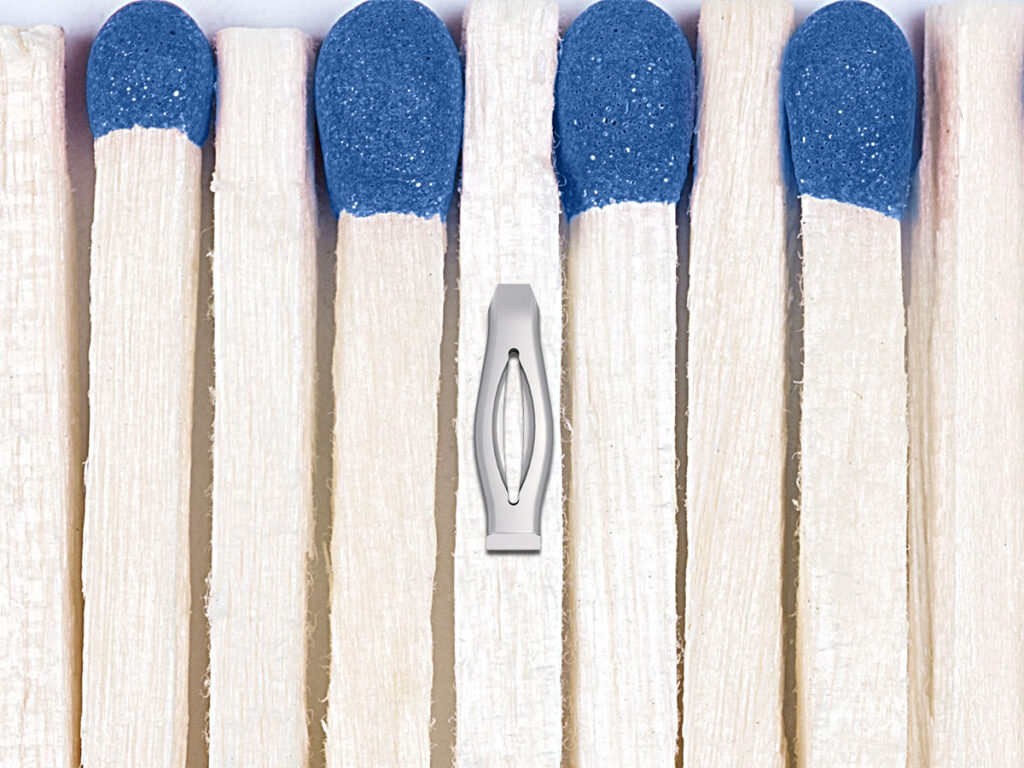

EloPin® by hapema

Another great example of our precision performance is EloPin®, the most secure mechanical connector for printed circuit boards, which allows chipless press-fitting into a wide range of materials. The hapema EloPin® is suitable for a wide range of applications from the automotive industry to the telecommunications and medical technology sectors.

This "needle eye" press-fit zone with its ultra-reliable connection properties places particularly high demands on manufacturing precision and can therefore only be produced by a handful of manufacturers.

Just a few of our many products